// libs for the display

#include <Elegoo_GFX.h>

#include <Elegoo_TFTLCD.h>

#include <TouchScreen.h>

#include <SPI.h>

#include <Wire.h>

// libs for the sensor

#include "Adafruit_MAX31855.h"

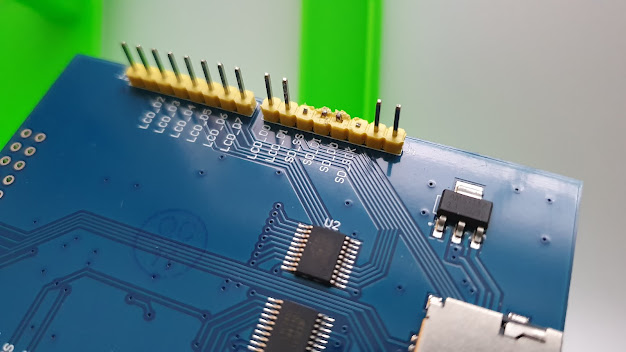

// display stuff, these settings are taken from Elegoo code

#define LCD_CS A3

#define LCD_CD A2

#define LCD_WR A1

#define LCD_RD A0

#define LCD_RESET A4

#define YP A3

#define XM A2

#define YM 9

#define XP 8

#define TS_MINX 120

#define TS_MAXX 900

#define TS_MINY 70

#define TS_MAXY 920

#define STATUS_X 10

#define STATUS_Y 65

// pin definition for the MAX31855 sensor board, I removed them from the display, where they are used for the SD card

#define MAXDO 12

#define MAXCS 13

#define MAXCLK 11

// define the relais at pin 10 (also removed from the display)

const int relaisIN1 = 10;

// a couple of used variables

unsigned long myTime, newTime, startTime, startTwomin, stopTwomin, newTwomin;

// maxtemp,interval temp, interval time, max time

int parameters[4] = {1050, 100, 60, 30};

int runs = 0;

float rohtemp = 650;

int timepos = 10;

float steptemp = 0;

int looptime = 0;

int oldpos = 0;

int tempcounter = 0;

int simfactor = 1;

int finished = 0;

unsigned long graphcolor = 0xF800;

// #define BLUE 0x001F

float temp = 0;

float tempinc = 10;

float oldtemp = 0;

float deltemp = 0;

float loops = 0;

float numloops = 1;

// initialize the thermocouple sensor

Adafruit_MAX31855 thermocouple(MAXCLK, MAXCS, MAXDO);

// initialize the LCD display and touchscreen

Elegoo_TFTLCD tft(LCD_CS, LCD_CD, LCD_WR, LCD_RD, LCD_RESET);

TouchScreen ts = TouchScreen(XP, YP, XM, YM, 300);

// define array of 14 buttons .. yeah I know only 13 are on the screen, too lazy to fix that ;-)

Elegoo_GFX_Button buttons[14];

void setup(void) {

Serial.begin(9600);

pinMode(relaisIN1, OUTPUT);

delay(1000);

while (!Serial) delay(1); // wait for Serial on Leonardo/Zero, etc

delay(500);

Serial.print("Initializing sensor...");

if (!thermocouple.begin()) {

Serial.println("ERROR.");

while (1) delay(10);

}

Serial.println("DONE.");

Serial.println(F("TFT LCD test"));

Serial.println(graphcolor);

tft.reset();

temp = thermocouple.readCelsius();

uint16_t identifier = 0x9341;

tft.begin(identifier);

tft.setRotation(2);

tft.fillScreen(0x0000);

tft.setTextSize(2);

tft.setCursor(10, 2); tft.print("mx Temp:");

tft.setCursor(10, 20); tft.print("iv Temp:");

tft.setCursor(10, 38); tft.print("iv Zeit:");

tft.setCursor(10, 56); tft.print("mx Zeit:");

tft.setCursor(10, 153); tft.print("mx Temp:");

tft.setCursor(10, 187); tft.print("iv Temp:");

tft.setCursor(10, 222); tft.print("iv Zeit:");

tft.setCursor(10, 257); tft.print("mx Zeit:");

tft.setTextColor(0xB596);

tft.setCursor(110, 2); tft.print(parameters[0]); tft.print(" 'C");

tft.setCursor(110, 20); tft.print(parameters[1]); tft.print(" 'C");

tft.setCursor(110, 38); tft.print(parameters[2]); tft.print(" Min");

tft.setCursor(110, 56); tft.print(parameters[3]); tft.print(" Min");

tft.setCursor(0, 0);

buttons[1].initButton(&tft, 60, 90, 112, 30, 0xFFFF, 0xDDF2, 0xFFFF, "Keramik", 2);

buttons[2].initButton(&tft, 180, 90, 112, 30, 0xFFFF, 0x94B2, 0xFFFF, "Schmelze", 2);

buttons[3].initButton(&tft, 60, 125, 112, 30, 0xFFFF, 0xD340, 0xFFFF, "Glasur", 2);

buttons[4].initButton(&tft, 180, 125, 112, 30, 0xFFFF, 0x8AC8, 0xFFFF, " ", 2);

buttons[5].initButton(&tft, 150, 160, 53, 30, 0xFFFF, 0x2C5C, 0xFFFF, "-", 2);

buttons[6].initButton(&tft, 210, 160, 53, 30, 0xFFFF, 0x2C5C, 0xFFFF, "+", 2);

buttons[7].initButton(&tft, 150, 195, 53, 30, 0xFFFF, 0x2C5C, 0xFFFF, "-", 2);

buttons[8].initButton(&tft, 210, 195, 53, 30, 0xFFFF, 0x2C5C, 0xFFFF, "+", 2);

buttons[9].initButton(&tft, 150, 230, 53, 30, 0xFFFF, 0x2C5C, 0xFFFF, "-", 2);

buttons[10].initButton(&tft, 210, 230, 53, 30, 0xFFFF, 0x2C5C, 0xFFFF, "+", 2);

buttons[11].initButton(&tft, 150, 265, 53, 30, 0xFFFF, 0x2C5C, 0xFFFF, "-", 2);

buttons[12].initButton(&tft, 210, 265, 53, 30, 0xFFFF, 0x2C5C, 0xFFFF, "+", 2);

buttons[13].initButton(&tft, 60, 300, 112, 30, 0xFFFF, 0x0400, 0xFFFF, "START", 2);

for (uint8_t b = 1; b < 14; b++) {

buttons[b].drawButton();

}

steptemp = parameters[0];

}

#define MINPRESSURE 10

#define MAXPRESSURE 1000

// read temperature from sensor or do uncomment temp=temp+0.001*simfactor; for simulation

void gettemp() {

temp = thermocouple.readCelsius();

// temp = temp + 0.001 * simfactor;

}

void relais(int onoff) {

switch (onoff) {

case 0: if (digitalRead(relaisIN1) == HIGH) {

digitalWrite(relaisIN1, LOW); // relais1 off

// lower the temperature for simulation

Serial.println("off");

simfactor = -1;

} break;

case 1: if (digitalRead(relaisIN1) == LOW) {

digitalWrite(relaisIN1, HIGH); // relais1 on

// increase the temperature for simulation

simfactor = +1;

Serial.println("on");

} break;

}

}

void dostop() {

relais(0);

graphcolor = 0x001F;

tempcounter++;

if (tempcounter == 1000) {

tft.setCursor(150, 22); tft.setTextSize(2); tft.setTextColor(0x0000); tft.print(round(deltemp));

tft.setCursor(150, 22); tft.setTextSize(2); tft.setTextColor(0x07FF); tft.print(round(temp));

deltemp = temp;

tempcounter = 0;

}

if (newTwomin > (startTwomin + 120000)) {

drawtemp();

startTwomin = newTwomin;

}

if (temp < 30) {

while (1) {}

}

}

void drawtemp() {

Serial.println("draw");

tft.drawLine(timepos, 308 - (round(oldtemp / 5)), timepos + 1, 308 - (round(temp / 5)), graphcolor);

timepos = timepos + 1;

oldtemp = temp;

}

void intervall(long laufzeit) {

newTime = millis();

// set a start time

startTime = millis();

// start the two minute timer for the graph

// repeat as long as the running time is lower than the interval time laufzeit*60*1000 (minutes to seconds to milliseconds)

while ((millis() - startTime) < (laufzeit * 60 * 1000)) {

// Serial.print("L");

newTwomin = millis();

gettemp();

// draw the curve when the timer hits two minutes, then reset the timer

if (newTwomin > (startTwomin + 120000)) {

drawtemp();

startTwomin = newTwomin;

}

// if the temperature gets higher than the set temperature shut down the heating

if (temp > steptemp + 3) {

relais(0);

}

// if the temperature gets too low enable the heating again

if (temp < steptemp - 3) {

relais(1);

}

printtemp();

} // while end

loops = loops + 1;

// if there is only one heating intervall stop once it is done

if (parameters[1] == 0) {

finished = 1;

timepos = 10;

relais(0);

}

// once reached the biscuit firing go to the final temperature and hold it

if (steptemp == rohtemp) {

// heat up to the final temperature

steptemp = parameters[0];

// set the heating time for the final heating

parameters[2] = parameters[3];

} else {

// increase the temperature to the next step

steptemp = (steptemp + parameters[1]);

relais(1);

}

// if temperature is higher than biscuit them set the current target to biscuit temperature

if (steptemp > rohtemp && steptemp < parameters[0]) {

steptemp = rohtemp;

}

if (temp > parameters[0] - 5) {

relais(0);

timepos = 10;

dostop();

}

}

// this function sets the presets

void setparameters(int x, int y, int color, int mt, int it, int iz, int mz) {

tft.setTextColor(0x0000);

tft.setCursor(x, y); tft.print(parameters[0]); tft.print(" 'C");

tft.setCursor(x, y + 18); tft.print(parameters[1]); tft.print(" 'C");

tft.setCursor(x, y + 36); tft.print(parameters[2]); tft.print(" Min");

tft.setCursor(x, y + 54); tft.print(parameters[3]); tft.print(" Min");

parameters[0] = mt;

parameters[1] = it;

parameters[2] = iz;

parameters[3] = mz;

tft.setTextColor(color);

tft.setCursor(x, y); tft.print(mt); tft.print(" 'C");

tft.setCursor(x, y + 18); tft.print(it); tft.print(" 'C");

tft.setCursor(x, y + 36); tft.print(iz); tft.print(" Min");

tft.setCursor(x, y + 54); tft.print(mz); tft.print(" Min");

}

// this function updates the values time and temperature when pressing +/-

void incdec(int x, int y, int color, int orig, int factor) {

tft.setCursor(x, y); tft.setTextColor(0x0000); tft.print(parameters[orig]); tft.print(" 'C");

tft.setCursor(x, y); tft.setTextColor(0x0000); tft.print(parameters[orig]); tft.print(" Min");

newTime = millis();

// wenn touchscreen länger gedrückt beschleunige auf 10er Schritte, ansonsten +/- 1

if (newTime - myTime < 160) {

parameters[orig] = parameters[orig] + 10 * factor;

} else {

parameters[orig] = parameters[orig] + 1 * factor;

}

if (parameters[orig] < 0) parameters[orig] = 0;

tft.setCursor(x, y); tft.setTextColor(color); tft.print(parameters[orig]);

if (orig > 1) {

tft.print(" Min");

} else {

tft.print(" 'C");

}

myTime = millis();

}

void printtemp() {

tempcounter++;

if (tempcounter == 1000) {

// print the old temp with black

tft.setCursor(150, 22); tft.setTextSize(2); tft.setTextColor(0x0000); tft.print(round(deltemp));

// print the current temp

tft.setCursor(150, 22); tft.setTextSize(2); tft.setTextColor(0xB596); tft.print(round(temp));

deltemp = temp;

tempcounter = 0;

}

}

void loop(void) {

// some copied routines from elegoo for the touch control and buttons

digitalWrite(13, HIGH);

TSPoint p = ts.getPoint();

digitalWrite(13, LOW);

pinMode(XM, OUTPUT);

pinMode(YP, OUTPUT);

if (p.z > MINPRESSURE && p.z < MAXPRESSURE) {

p.x = map(p.x, TS_MINX, TS_MAXX, tft.width(), 0);

p.y = (tft.height() - map(p.y, TS_MINY, TS_MAXY, tft.height(), 0));

}

// go thru all the buttons, checking if they were pressed

for (uint8_t b = 0; b < 14; b++) {

if (buttons[b].contains(p.x, p.y)) {

buttons[b].press(true); // tell the button it is pressed

} else {

buttons[b].press(false); // tell the button it is NOT pressed

}

}

if (runs == 1) {

// clear screen

tft.fillScreen(0x0000);

// draw grid

tft.setTextColor(0xEEEE);

tft.setCursor(2, 22); tft.print("Temperatur:");

for (uint8_t i = 1; i < 27; i++) {

tft.drawLine(10, 38 + i * 10, 230, 38 + i * 10, 0x5AEB);

if ((i - 1) % 3 == 0) {

tft.drawLine(0 + i * 10, 48, 0 + i * 10, 309, 0x00EB);

} else {

tft.drawLine(0 + i * 10, 48, 0 + i * 10, 300, 0x00EB);

}

tft.setTextSize(1); tft.setTextColor(0xB596);

tft.setCursor(0, 30 + i * 10);

tft.print(1350 - i * 50);

}

// draw coords X axis, sadly no linear spacing so one by one

tft.setCursor(8, 310); tft.print("0");

tft.setCursor(35, 310); tft.print("60");

tft.setCursor(62, 310); tft.print("120");

tft.setCursor(92, 310); tft.print("180");

tft.setCursor(121, 310); tft.print("240");

tft.setCursor(152, 310); tft.print("300");

tft.setCursor(182, 310); tft.print("360");

tft.setCursor(212, 310); tft.print("420");

if (parameters[1] > 0) {

numloops = ceil(rohtemp / parameters[1]);

}

// if there are no more heating intervals go to the main temperature, otherwise go to next loop

if (parameters[1] == 0 && loops < 1) {

steptemp = parameters[0];

parameters[2] = parameters[3];

} else if (parameters[1] > 0 && loops < numloops) {

steptemp = parameters[1];

}

// relais on, start heating

relais(1);

// go to the heating loops

runs = 2;

}

if (runs == 2) {

// since there is no rtc, create a timer

if (startTime == 0) {

startTime = millis();

}

// zwei Minuten Timer starten

if (startTwomin == 0) {

startTwomin = millis();

}

// read temperature from sensor (or simulate)

gettemp();

// for how long is the program running already?

newTime = millis();

newTwomin = millis();

// draw graph all two minutes

if (newTwomin > (startTwomin + 120000)) {

drawtemp();

startTwomin = newTwomin;

}

// if destination temperature reached start the heating loop

if (temp > steptemp - 1 && parameters[1] > 0 && loops < numloops + 1) {

intervall(parameters[2]); // loop time

} else if (temp > parameters[0] - 1 && loops < 1) {

intervall(parameters[3]); // final time

}

// draw cooling graph in blue

if (numloops == loops) {

graphcolor = 0x001F;

}

printtemp();

} else {

for (uint8_t b = 1; b < 14; b++) {

if (buttons[b].justReleased()) {

buttons[b].drawButton(); // unpressed

}

if (buttons[b].justPressed()) {

buttons[b].drawButton(true); // pressed

switch (b) {

// presets

case 1: setparameters(110, 2, 0xB596, 1050, 100, 60, 30); break; // Keramik

case 2: setparameters(110, 2, 0xB596, 250, 0, 0, 30); break; // Schmelze

case 3: setparameters(110, 2, 0xB596, 1050, 0, 0, 30); break; // Glasur

case 5: incdec(110, 2, 0xB596, 0, -1); break; // if (parameters[0]<30) parameters[0]=30; - maxtemp

case 6: incdec(110, 2, 0xB596, 0, 1); break; // if (parameters[0]>1050) parameters[0]=1050; + maxtemp

case 7: incdec(110, 20, 0xB596, 1, -1); break; // if (parameters[1]<30) parameters[1]=30; - ivtemp

case 8: incdec(110, 20, 0xB596, 1, 1); break; // if (parameters[1]>1050) parameters[1]=1050; + ivtemp

case 9: incdec(110, 38, 0xB596, 2, -1); break; // - iv Time

case 10: incdec(110, 38, 0xB596, 2, 1); break; // + iv Time

case 11: incdec(110, 56, 0xB596, 3, -1); break; // - max Time

case 12: incdec(110, 56, 0xB596, 3, 1); break; // + max Time

case 13: runs = 1; break; // start pressed

}

// little delay to prevent uncontrolled ui reactions

delay(100);

}

}

}

}